- casa

- >

- notícia

- >

- O que é folha EB?

- >

O que é folha EB?

2024-08-14 15:30

With the development of modern industry and building materials, EB Sheet has gradually become a high-performance material that has attracted much attention. This article will introduce the definition, production process, characteristics, application scenarios and competitive advantages of EB Sheet in detail, and help readers fully understand this new material.

What is EB Sheet?

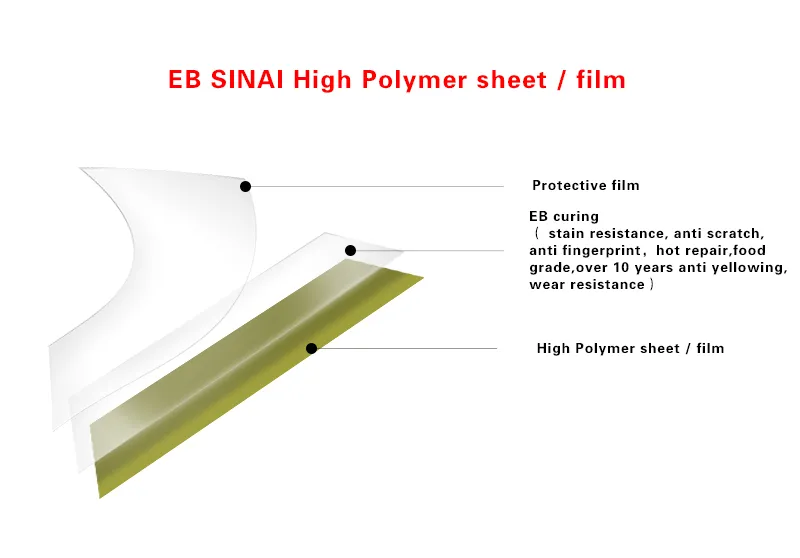

EB Sheet, or Electron Beam Cured Sheet, is a composite sheet that uses electron beam technology to cure the coating. Unlike traditional thermal curing and UV curing processes, the electron beam curing process can quickly cure the coating at room temperature, and has the characteristics of high efficiency, environmental protection, and excellent performance. EB Sheet is usually composed of a substrate (such as wood fiberboard, plastic board, metal plate, etc.) and an electron beam cured coating, and is widely used in furniture, architectural decoration, automobile manufacturing and other fields.

How is EB Sheet made?

The production process of EB Sheet: substrate preparation (MDF, HDF), coating application (resin, pigment, additives), electron beam curing (rapid curing to form a film), surface treatment (polishing, grinding), finished product inspection and packaging.

1. Substrate preparation:

Select a suitable substrate according to the purpose of the final product, such as medium-density fiberboard (MDF), high-density fiberboard (HDF), plastic board or metal board. The substrate needs to be cleaned, dried and treated to ensure that its surface is flat and clean, which is convenient for the subsequent coating to adhere.

2. Coating:

Uniformly apply a layer of special coating on the surface of the substrate. The coating usually contains resin, pigment, additives and other ingredients, which can be quickly cured under electron beam irradiation. The coating process requires uniform coating thickness and strong adhesion to ensure the stable performance of the final product.

3. Electron beam curing:

The coated board is sent to the electron beam curing equipment, and the molecules in the coating are cross-linked through high-energy electron beam irradiation, and quickly cured into a film. The electron beam curing process does not require high-temperature treatment, and the curing process is efficient and energy-saving, while avoiding the impact of high temperature on the substrate.

4. Surface treatment:

The surface of the cured board is polished, ground, coated with a protective layer, etc. to improve its appearance quality and durability. According to customer needs, personalized treatments such as color printing and embossing can also be performed.

5. Finished product inspection and packaging:

The processed EB Sheet is strictly inspected for quality to ensure that it meets relevant standards and customer requirements. Qualified products are packaged and sent to the market for sale.

What are the characteristics of EB Sheet?

The characteristics of EB Sheet: high efficiency and environmental protection (no volatile organic compounds), excellent surface performance (high coating hardness and good wear resistance), strong chemical resistance (not susceptible to corrosion and erosion), dimensional stability, and good processing performance.

1. High efficiency and environmental protection:

The electron beam curing process does not require solvents, and the curing process does not produce volatile organic compounds (VOCs), which meets environmental protection requirements. In addition, the fast curing speed and low energy consumption help reduce production costs and environmental impact.

2. Excellent surface performance:

The surface of EB Sheet is smooth and flat, with high gloss and good decorative effect. The coating has high hardness, good wear resistance, and excellent scratch resistance, which is suitable for high-frequency use places.

3. Strong chemical resistance:

EB Sheet has good tolerance to a variety of chemicals, is not susceptible to corrosion and erosion, and is suitable for humid and corrosive environments.

4. Dimensional stability:

The electron beam curing process is carried out at room temperature, which will not cause thermal deformation of the substrate, ensuring the dimensional stability and shape retention of the sheet.

5. Good processing performance:

EB Sheet can be cut, drilled, engraved and other mechanical processing to meet different design requirements and has excellent processing performance.

What are the application scenarios of EB Sheet?

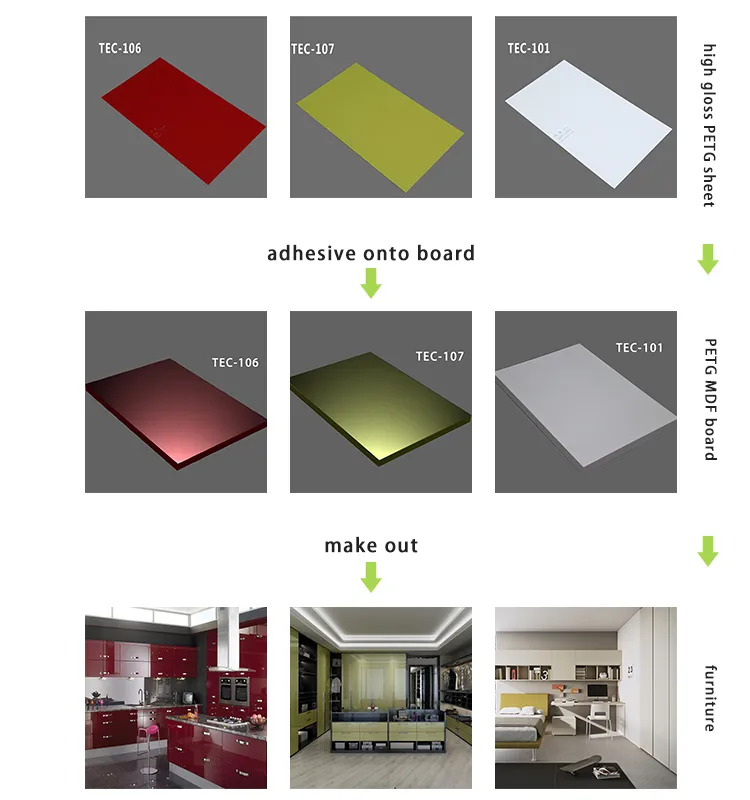

The application scenarios of EB Sheet are: furniture manufacturing (furniture manufacturing, such as cabinets, wardrobes), interior decoration (walls, ceilings, door panels), automobile manufacturing (interior decoration parts, dashboards), electronic products (electronic product housings, display frames), commercial displays (shopping malls, exhibitions, etc.).

1. Furniture manufacturing:

EB Sheet is widely used in furniture manufacturing, such as cabinets, wardrobes, tables and chairs, due to its excellent surface properties and environmental protection characteristics. Its high gloss and wear resistance make the furniture not only beautiful and generous, but also have a long service life.

2. Interior decoration:

EB Sheet is used for wall, ceiling, door panel and other decorations to meet the decoration needs of different styles. Its high gloss and rich color selection can create a high-end and fashionable indoor atmosphere.

3. Automobile manufacturing:

In the field of automobile manufacturing, EB Sheet is used for interior decoration parts, dashboards, door panels and other parts. Its wear resistance and chemical resistance ensure the beauty and durability of automobile interiors.

4. Electronic products:

EB Sheet is used for electronic product housings, display screen frames and other parts. It has high gloss and good wear resistance, which improves the appearance quality and service life of electronic products.

5. Commercial display:

EB Sheet is used for display cabinets, display racks, etc. in shopping malls, exhibitions and other places. It is both beautiful and practical. Its smooth surface and bright colors can enhance the display effect of goods.

Market competitive advantages of EB Sheet

1. Environmental protection advantages:

With the enhancement of environmental awareness, consumers' demand for environmentally friendly materials is increasing. The environmental protection performance of EB Sheet gives it a significant advantage in market competition. No organic solvents are used in its production process, which reduces pollution to the environment and meets modern environmental protection standards.

2. Performance advantages:

EB Sheet's surface performance, chemical resistance and dimensional stability make it excellent in practical applications and meet a variety of high-end application needs.

3. Price advantage:

Compared with some high-end materials, EB Sheet has a lower production cost and a more competitive price. Its high cost-performance ratio makes it an ideal choice for the mid-to-high-end market.

4. Processing advantage:

EB Sheet is easy to process and can be formed and processed through a variety of processes to meet the needs of different application fields, which enhances its market competitiveness.

Conclusion

As a high-performance and environmentally friendly new material, EB Sheet has gradually occupied an important position in the industrial and building materials market with its excellent surface properties, chemical resistance, dimensional stability and diversified application scenarios.

In the future, with the continuous advancement of technology and changes in market demand, EB Sheet will continue to optimize and upgrade to provide consumers with more high-quality choices.